Free L i t e r a t u r e O f f e r e d On N e w O i l y W a t e r S e p a r a t or By H a m w o r t h y E n g i n e e r i ng

Literature is being offered detailing a compact, highly efficient oily water separator, the latest product being marketed by the Pump & Compressor Division of Hamworthy Engineering Limited of Poole, Dorset, U.K., to combat pollution by ships' bilge and ballast discharge.

Hamworthy spent over two years in research and development of the unit which has been granted IMO approval in accordance with A393(X) and certification by marine classification societies.

The unit is a two-stage device, the first stage being a gravity tank and the second a plate-type separator. Two identical positive displacement pumps are mounted on top of the fabricated steel separator vessel.

Most existing separators pump oily water from the bilges into a separator. This action breaks down the oil into tiny droplets making separation more difficult.

The Hamworthy system draws oil into the separator and uses the natural gravitational differential to achieve a high degree of primary separation.

The unit is built and supplied as a complete module requiring no additional equipment. Ship- yard installation work is limited to connecting electrical and inlet and outlet connections. No filters are required and it is easily serviced. The fully automatic unit has capacities up to 5 tons per hour.

For a free copy of the brochure, Write 36 on Reader Service Card

Read Free L i t e r a t u r e O f f e r e d On N e w O i l y W a t e r S e p a r a t or By H a m w o r t h y E n g i n e e r i ng in Pdf, Flash or Html5 edition of March 1983 Maritime Reporter

Other stories from March 1983 issue

Content

- A S E A A w a r d e d $ 3 . 5 - M i l l i on O r d e r For S h a f t G e n e r a t o rs — L i t e r a t u r e A v a i l a b le page: 5

- Rivera, Willis Join Staff Of Designers & Planners page: 6

- R a y t h e o n Service A w a r d ed $ 1 - M i l l i o n Contract For T A K X Equipment page: 6

- Top M a n a g e m e n t C h a n g es A n n o u n c e d By D o v e r - N o r r is page: 6

- Newport News Lifts 890-Metric-Ton Assembly Onto Carrier Roosevelt -Largest Ever For Naval Vessel page: 8

- Todd Houston Accepts Delivery Of New Drydock From Bender page: 8

- ITC O f f e r s Brochure D e s c r i b i n g Its N ew H e a v y - L i f t Vessel page: 8

- J.C. Leighton Elected Executive V P Of Raymond Kaiser Engineers page: 9

- Krupp MaK Diesel Moves To New Headquarters For North American Operations page: 10

- Free L i t e r a t u r e O f f e r e d On N e w O i l y W a t e r S e p a r a t or By H a m w o r t h y E n g i n e e r i ng page: 10

- N e w Firm W i l l A d v i se M a n u f a c t u r e r s O n H ow To Sell To N a vy page: 10

- S w i f t s h i p s To B u i l d T wo F i r e / R e s c u e Boats For P l a q u e m i n e s Parish page: 11

- N e w S h i p b u i l d e r s Council P r e s i d e n t Selected page: 11

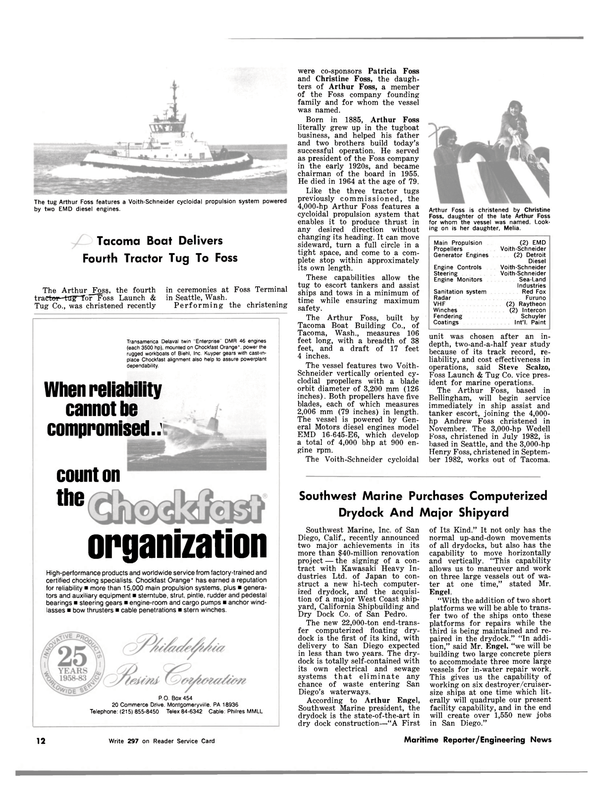

- Tacoma Boat Delivers Fourth Tractor Tug To Foss page: 12

- Southwest Marine Purchases Computerized Drydock And Major Shipyard page: 12

- 1983 RTCM ASSEMBLY page: 12

- New Puget Sound Section Of MTS Elects Officers page: 13

- Halter Marine Delivers Second Of Four Supply Boats To Point Express, Ltd. page: 14

- $121-Million Contract Awarded To Davie For Gulfspan-Class Ferry page: 16

- C e n t r i c o O f f e r s Free 1 2 4 - P a g e G u i d e b o ok On W e s t f a l i a Oil S e p a r a t o rs page: 16

- Moore McCormack Completes Sale Of Cargo Liners page: 17

- New Brochure Contains Raytheon Radar Comparison And Offer Of Free Life Vests page: 17

- Bender To Offer New Ice-Class Anchor Handling Tug/Supply Vessel page: 18

- Maritime Technology For A Changing World page: 18

- Brochure Offered On New Electrolytic Anti-Fouling System For Problem Areas page: 19

- CRC Celebrates Its 50th Anniversary —Brochures Available page: 19

- Todd Reports Increase In Sales And Earnings page: 22

- Newport News Reports Fourth Year Of Higher Operating Income page: 23

- Iowa Marine Delivers M/V Blanche V To Gibbons Marine page: 24

- EMD Introduces New Fuel-Efficient Diesel —Brochure Available page: 24

- LeCompte Named General Manager Of Bethlehem's Great Lakes Division page: 25

- Wesley Wheeler Appointed U.S. Representatives For Hapag-Lloyd Shipyard page: 26

- $1.1 -Million Contract For VHF-FM Systems Awarded Rockwell-Collins Itaiiana page: 26

- Petronas Commissions Its First Proet-Built Jackup page: 26

- Honeywell Forms New Undersea Sensor Group page: 27

- Castelvecchi Named Corporate Purchasing Agent At Ships Supply page: 27

- Thomas M a r i n e Delivers 24-Foot Survey Boat To N . Y . - N J . Port Authority page: 27

- Charles Lynch Elected AIMS Board Chairman page: 28

- Heerema Group Acquires Big Inch Marine Systems page: 28

- D o r a n - A l a b a m a O f f e r s Free Brochure O n Propellers A n d Repair Services page: 28

- S a l w i c o O f f e r s L i t e r a t u re O n S a l - G l a s Protective P r i m e r l e s s M a r i n e C o a t i n gs page: 29

- Minority-Owned Shipyard Organized In Portland page: 30

- Alio International Rubber Appoints Robert Salter As Sales Manager page: 30

- New Raytheon RAYPATH ARPA Meets IMO Requirements —Brochure Available page: 31

- William Law Elected To Board Of Twin City Barge page: 32

- American Lohmann Offers Free Literature On Marine Gearboxes page: 32

- CAB Develops Portable Steel Grit Recovery System —Free Literature Offered page: 32

- Bell Halter Begins Production Of First LCAC For Amphibious Forces page: 32

- M.A.N. To Build Three Floating Cranes With Voith-Schneider Propulsion page: 33

- D r a v o M e c h l i n g A n n o u n c es M a n a g e m e n t C h a n g e s In S o u t h e r n O p e r a t i o ns page: 33

- A m e r i c a n W a t e r w a ys S h i p y a r d C o n f e r e n ce O f f i c e r s Elected page: 33

- Daewoo Christens Two Jackup Rigs For Dual Drilling Co. page: 34

- H o u s t o n S y s t e m s C o m p l e t es C u s t o m W o r k O n 4 N e w Rigs page: 34

- G l a d d i n g Hearn Delivers Largest Self-Propelled U.S. Skimmer To Clean Sound page: 36

- C e n t r i c o F o r m s M i n e r al O i l G r o u p , L o h m e y er N a m e d H e a d O f U n it page: 37

- Lykes Appoints Three In Central Atlantic Division page: 38

- Lavalin Ocean Systems Formed In Canada To Provide Underwater Service page: 38

- LEEVAC Shipyards Will Produce World Class ME 500 Tug Supply Vessel page: 38

- C r o s b y G r o u p A n n o u n c es P r o m o t i o n s O f Sales A nd O p e r a t i o n s Executives page: 38

- W a u k e s h a Bearings N a m ed M a s t e r U.S. D i s t r i b u t or O f T h o r d o n C o m p o u n ds page: 38

- Brown & Root Elects Three Vice Presidents In Marine Operations page: 39

- n t e r o c e a n S t e a m s h i p Buys Lykes S t e a m s h i p For $ 1 5 0 - M i l l i o n page: 39

- Alaskan Office Opened By Global Marine Divisions page: 40

- Halter To Build Deepwater, ME 202s And ME 303s In The United States page: 40

- Robin Hood Fleeting Names Hines Vice President page: 41

- Russellstoll To Market Northern Rig Lites Products —Literature Available page: 41

- S N A M E To P l a y M a j o r Role I n C o n v e r t i n g M i l s p e cs T o C o m m e r c i a l S t a n d a r ds page: 41

- S P C / I R E A P S Seeks Papers For D e l i v e r y At Tenth Technical S y m p o s i um page: 42

- V e n e z u e l a n Y a r d A w a r ds $ 1 . 2 - M i l l i o n Production Line C o n t r a c t To TTS page: 42

- 2 . 2 - M i l l i o n N a v y C o n t r a ct For T e c h n i c a l S e r v i c es A w a r d e d T o T r a c or page: 43

- M a r A d R e l e a s e s R e p o rt O n N o v e l " O u t s i d e H u l l" P r o p u l s i o n S y s t em page: 43

- SECOND ANNUAL NATIONAL MARITIME SHOW page: 46

- Halter Delivers Catug To C a l i f o r n i a And H a w a i i Sugar Co. page: 48

- G l o b a l M a r i n e Forms N e w Business U n it page: 49

- Fisher M a r i t i m e To H o ld E i g h t W o r k s h o p s On L i a b i l i t y A v o i d a n ce page: 49

- Tideland Signal Names Two New Vice Presidents page: 52

- First Of Five 20,000-Dwt Cargo Vessels Delivered By Valmet To V /O Sudoimport page: 52

- Battleship Iowa Enters Ingalis Yard For Completion Of Reactivation And Modernization Contract page: 53

- C a r r i e r F o r r e s t a l ( C V 5 9 ) B e g i ns SLEP A t P h i l a d e l p h i a N a v y Y a rd page: 53

- Honeywell Names Holman Vice President & General Manager, Marine Division page: 54

- Savings Up To 30 Percent Detailed In Brochure On Avicon's New Fuel Monitor page: 56

- JRC Opens Offices In Australia, Singapore page: 56

- ASNE-Puget Sound Discusses The Soviet Navy page: 59

- Free 32-Page Report Details Test Results On New Fuel Efficient EMD Diesel page: 59

- Blount Establishes Subsidiary To Build Super-Fast Commuter Boats page: 60

- New Marine Impellers Described In Free Brochure page: 61

- Getty Plans Expansion Of California Marine Terminal Costing $60 To $100 Million page: 61

- Todd Delivers Frigate Ahead Of Schedule page: 62

- Seaward To Supply Buoys For Middle East Jackups —Literature Available page: 62

- Free Brochure Describes 48 Models Of Allied Hydraulic Marine Cranes page: 62

- Diaz Elected President Of Greater New Orleans Barge Fleeting Association page: 63

- Navy Awards Tracor $4.6-Million Contract For Submarine Program page: 63

- Navy Awards Lockheed Contract To Construct Third Dock Landing Ship page: 64

- Talon Technology To Provide Satellite Communications Systems page: 65

- MES Awarded Contract To Build Semisubmersible For Sonat Offshore Drilling page: 65

- Scientific Management Associates Announces Acquisition By New Owners page: 66

- Selesmar Of Italy Increases Capital Through Agreement With INI page: 67

- Farrell Reports $35-Million Turnaround — Sells Four Ships To U.S. Lines page: 67

- New Sofec CALM-Plus Terminal For West Malaysia —Literature Available page: 70

- Coastal Iron Works Installs 2,500-Ton-Capacity Steel Floating Drydock 'Mr. Pat' page: 82

- Microphor Europe GmbH Formed In Europe By Microphor And German Firm page: 83