Kranco Develops Automatic Synchronization Of Hoists Controls

An automatic synchronization of hoists control (ASH) for dual drives up to 500 horsepower has been developed by Kranco, Inc., of Houston.

Designed to increase wire rope life and to provide ease of operation for Major Conference On Oil crane operators, the system is primarily utilized for mechanical bucket hoisting/lowering and open/ close functions such as those used on ship unloaders/loaders.

Though wire rope life can be maximized by utilizing the correct type of wire rope for the particular job, and the proper sizing of sheaves, it also depends on the proper loading of the ropes. The ASH drive system uses a true speed control drive, D.C. variand able voltage and the addition of a programmable logic controller and encoders on the hoist. The logic controller and encoders ensure that the bucket is fully closed prior to lifting the load and that the closing lines and holding lines raise the load together, creating equal loading on the ropes. In the lowering mode the bucket automatically opens at the start of the lowering motion through the open/close lines prior to Drovinthe lowering motion energizing. The open motion and the lower motion then synchronously lower the load, dividing the loading between the two sets of ropes.

Since 1956, Kranco, Inc. has been manufacturing ship unloaders/loaders (hoist type), rack and pinion overhead and gantry cranes and is a major innovator of drive systems including variable voltage and variable frequency speed control systems.

For additional information on Kranco's ASH system or other product line items, Circle 124 on Reader Service Card

Read Kranco Develops Automatic Synchronization Of Hoists Controls in Pdf, Flash or Html5 edition of May 1992 Maritime Reporter

Other stories from May 1992 issue

Content

- New Quality Assurance And Environmental/Safety Directors At IMC page: 4

- White House Promises New Merchant Marine Policy page: 4

- Major Changes Predicted For World Shipping Industry page: 6

- MHI Introduces New Bridge Operation Support System page: 6

- Comsat Develops Lightweight Satellite Battery page: 7

- Underwriters Told To Oppose Foreign Insurance Protectionism page: 7

- Fore River Yard Site Of $ 1.6-Billion Boston Project page: 7

- Overlay Finish For Fiber Ropes Improves Marine Performance page: 8

- MagneTek's PCB Testing Ensures EPA Compliance page: 9

- MagneTek's PCB Testing Ensures EPA Compliance page: 11

- NAVIONICS Introduces New Micro Chart Module page: 13

- Government And Oil Industry Begin Battle Over Oil Spill Assessments page: 13

- Inland Port Opened By Philadelphia page: 15

- IMC Announces New Board Of Directors, Corporate Officers page: 15

- AESA Appoints Gonzalez-Sama General Commercial Manager page: 17

- Ship Repair Revival Plan Outlined By San Francis page: 18

- Service Marine To Build HarrahVHammons Casino Boat For Illinois Operation page: 18

- Schichau Seebeckwerft Launches First Of Two Great White Fleet Reefers page: 19

- Del Norte Introduces Model 2006 GPS Receiver page: 19

- New Report Offers Detailed Study Of World Reefer Shipping page: 20

- R.H. Wager Opens New Mobile Office And Product Lines page: 20

- Double Christening Held For Avondale-Built National Marine Towboats page: 21

- DOUBLE HULL UPDATE page: 23

- New American Underpressure System —An Interim Solution page: 24

- 14 New Generation Double-Skin Tankers Being Built By Fincantieri page: 25

- Double-Hulled 'Patriot' Delivered By Samsung For Conoco Shipping page: 25

- HDW's Design For Double-Hull Tanker To Be European Standard page: 26

- Coast Guard Urges Unified Federal Spill Response Regulations page: 28

- Oil Pollution Act Spurs World Oil Industry To Drop Substandard Tankers page: 28

- Worldwide Tanker Order Book Hits 15-Year High page: 28

- Cruise Ship Zenith Delivered To Chandris Celebrity Cruises By Meyer Werft page: 29

- Diamond M-Odeco Teams With VODL To Enter Floating Production Market page: 29

- Newport News Markets Frigate Design To World page: 29

- Keel Layed For Cruise Ship Maasdam At Fincantieri Shipyard page: 29

- BOOM TIMES FOR KOREAN SHIPBUILDING page: 30

- MTlTs 595 Diesel Series Design Concept Proven Aboard Ferry 'Deutschland' page: 34

- Trinity Marine Awarded $31.2 Million Contract By U.S. Army To Build Two LSVs For Philippines Navy page: 36

- POSIDONIA 92 page: 37

- Tokimec's Marine Systems Division Offers Wide Range Of Navigation Equipment page: 38

- Port Of South Louisiana Plans To Turn Riverplex Into Intermodal Facility page: 39

- North Sea Operators Evaluating New Rig Concept For Long-Term Programs page: 39

- Boat Workers Rally For Luxury Tax Repeal page: 39

- EUROPEAN WORKBOAT SHOW page: 40

- Largest Cruise Liner Ever Built At Finnyards Delivered To Sally Line page: 41

- Bender Inc. Introduces New Portable Ground Fault Current Instrument page: 43

- NEI Syncrolift Receives Three Orders For Shiplifts And Transfer Systems page: 44

- Alden Electronics Introduces New Navtex AE-900 Receiver And Faxmate II Weather Chart Recorder page: 44

- 40th Annual Ft. Schuyler Forum Focuses On Marine Refrigeration And Diesel Engine Performance page: 44

- Glass Beads Demonstrated As Quick, Low-Cost Tool For Oil-Spill Cleanups page: 46

- Cruise Vessels To Be Built In Agreement Between McDermott/Swathtech page: 51

- Amclean Develops Multi-Nozzle Waterjet —Free Video Offered page: 51

- C. Plath Offers Free Color Brochure On Navipilot V page: 52

- New MSI-Operated Rotterdam Research, Training Center page: 52

- Guam Set To Become Key U.S. Military Outpost In Pacific page: 53

- CG Proposes New Rules For Unmanned Tanker Enginerooms page: 53

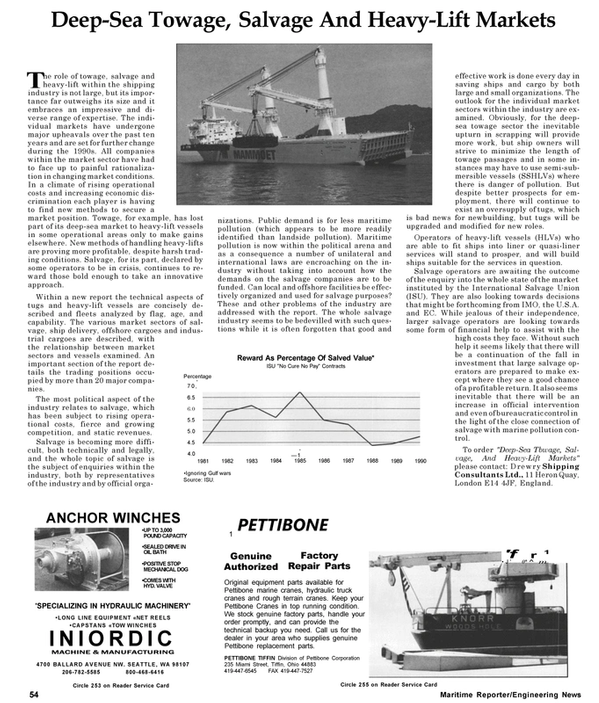

- Deep-Sea Towage, Salvage And Heavy-Lift Markets page: 54

- The Navy, MarAd, And RRF Deactivations page: 55

- Kranco Develops Automatic Synchronization Of Hoists Controls page: 56

- ABB Set To Get Power Supply System Job For Carnival's 'Imagination' page: 56

- Corps Of Engineers Asked To Fund More Renovations On Inland Waterways page: 57

- CD Based Government Logistics Data Available From USA Info Systems page: 57

- Major Conference On Oil Spill Laws & Response In Seattle, October '92 page: 58

- Open Committee On CG Oil Spill Legislation Completes 1 st Phase page: 58

- RORO 92 page: 60

- McQuay Chiller's QEII Experience Proves Reliability page: 61

- New Study Examines Under-Priced Ship Resale Market page: 62

- Raytheon Announces New Handheld VHF Radiotelephone page: 62

- Siemens To Supply Full Electrical System For New Research Vessel page: 62

- Propulsion System Demonstrator Powered By GE Gas Turbine page: 62

- Portland Box Volumes Up 25 Percent In February page: 62

- Washburn & Doughty Delivers Passenger/Auto Ferry Captain Henry Lee page: 64

- Crowley Maritime Celebrates 100 Years Of Service page: 64

- International Tug & Salvage Expo 1992 page: 66

- Capabilities Of Trinity Marine's New Beaumont Yard Highlighted page: 66

- NRC, Coastal And Phibro To Support Second National Response Network page: 67

- Mende Honored For Accomplishments In Marine Field page: 67

- U.S. NAVY FY 1993 page: 68

- Navy Expects To Award First Contracts From Sealift Fund In Early '93 page: 70

- MarAd Awards Yards Layberthing Contracts Worth $18 Million page: 71

- FY 1993 Budget For Coast Guard Shows Increase Over FY 1992 page: 71

- Appropriations Of $312 Million Requested For MarAd In FY 1993 page: 71

- Intermarine USA Launches Second Navy Minehunter page: 72

- DECK MACHINERY & CARGO-HAN DUNG EQUIPMENT page: 73

- USS Anzio, Ingall's 15th Aegis Cruiser Completed page: 81

- Wartsila's Vasa 32 Gas Diesel Now Ready For Global Sales page: 81

- Nichols Brothers Delivers 1,600-Passenger Dinner Boat For Hawaiian Service page: 83

- ABB Supplies Systems For New Icebreaker Being Built By Finnyards page: 84

- First Commercial Icebreaking Research Ship Delivered By North American page: 84